The BYC series tablet coating machine is an efficient and intelligent pharmaceutical equipment designed specifically for film coating, sugar coating, or enteric coating of tablets, pills, or microspheres. The equipment adopts advanced spray technology and hot air circulation system to ensure uniform and smooth coating, and conforms to GMP, FDA and other international standards. It is widely used in pharmaceutical, health products and food industries.

Feeding system: Tablets are loaded into the coating pot (drum) through an automatic feeding machine or manually.

Spray coating:

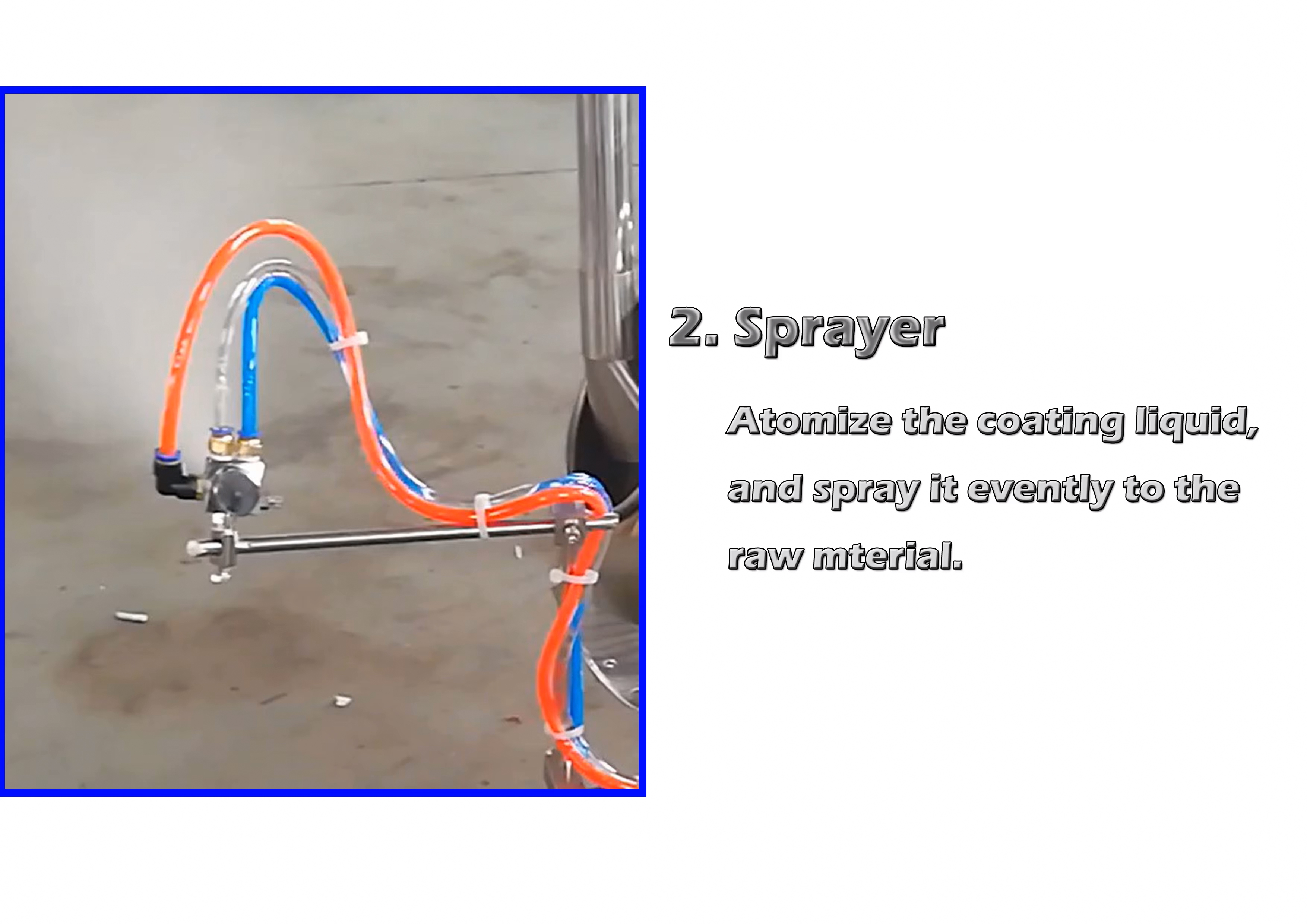

Spray gun atomization: The coating solution (film/sugar coating) is evenly sprayed onto the surface of the tablet by a precision spray gun.

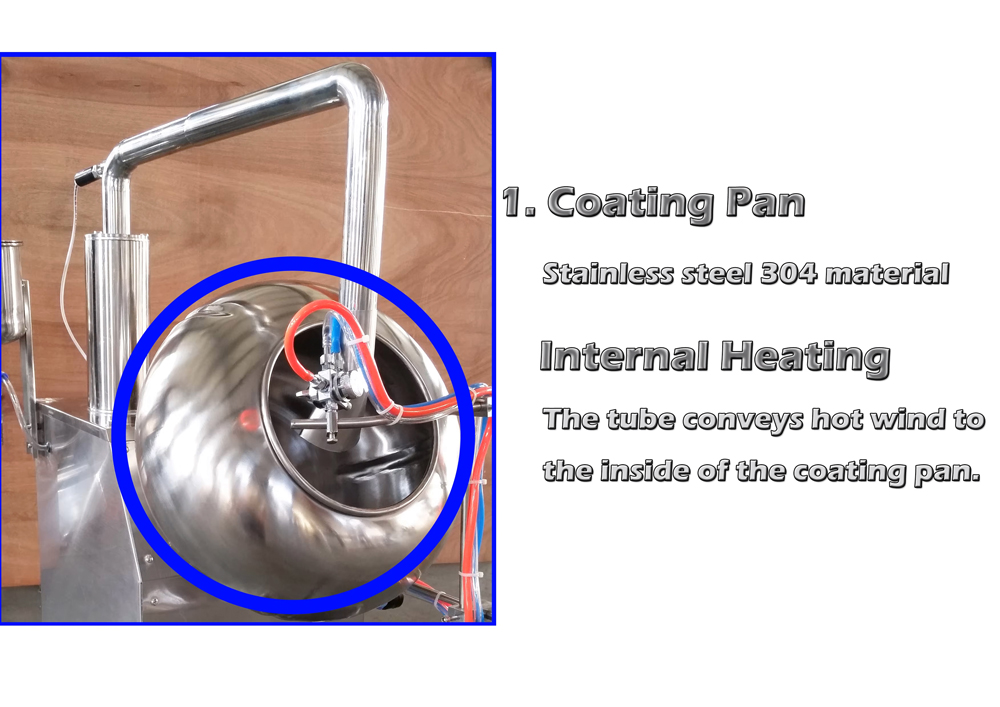

Hot air drying: Circulating hot air rapidly evaporates the solvent, forming a uniform coating film.

Dynamic rolling: The coating pot rotates at an adjustable speed (5-30 RPM) to ensure that the tablets are not wrapped in dead corners.

Discharge and cooling: After coating is completed, the tablets are automatically discharged and the coating film is solidified through the cooling section.

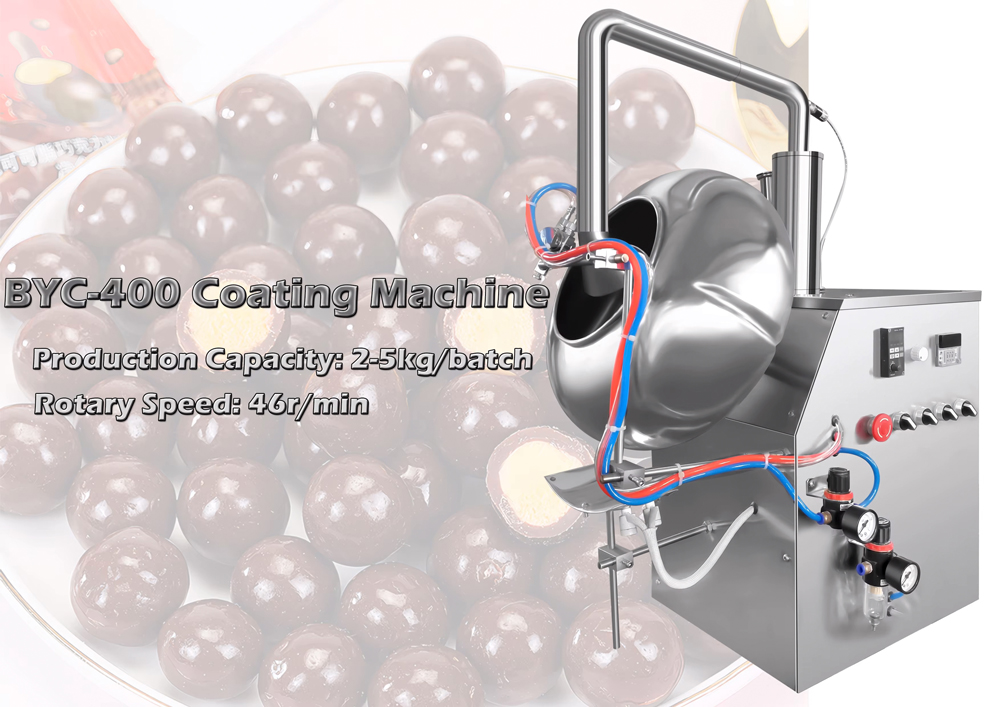

| Model | BYC-300 | BYC-400 | BYC-600 | BYC-800 | BYC-1000 | BYC-1250 |

|---|---|---|---|---|---|---|

| Capacity | 1-3kg/cycle | 2-5kg/cycle | 8-15kg/cycle | 30-50kg/cycle | 50-70kg/cycle | 80-150kg/cycle |

| Pot inclination | 42° | 42° | 30° | 30° | 30° | 30° |

| Motor power | 0.37kw | 0.37kw | 0.75kw | 1.1kw | 1.5kw | 2.2kw |

| Blower power | 60w | 60w | 100w | 200w | 200w | 370w |

| Pot volume | 1L | 1L | 5L | 8L | 10L | 20L |

| Heating power | 1.4KW | 1.4KW | 2kw | 3KW | 4KW | 6kw |

| Rotational speed | 0-46r/min | 0-46r/min | 0-40r/min | 0-32r/min | 0-32r/min | 0-28r/min |

| Weight | 49KG | 50KG | 150kg | 280KG | 300KG | 500KG |

Efficient polishing and dust removal: The powder removal effect is good, and the surface of the tablets is bright and clean.

Horizontal structure design: convenient for connecting subsequent equipment, such as metal inspection machines and packaging machines.

Compact structure: small footprint, flexible installation, and easy mobility.

All stainless steel manufacturing: Made of 304 or 316L stainless steel material, corrosion-resistant and easy to clean.

Low noise operation: minimal vibration and low noise during operation, safe and environmentally friendly.

Wide applicability: can handle circular and irregular tablets, with strong versatility.

Flexible adjustment: Supports adjusting the discharge height to meet the needs of different production lines.

Pharmaceutical industry: dust removal and polishing treatment after tablet pressing.

Health product industry: polishing and cleaning of chewable tablets and vitamin tablets.

Food industry: Candy and flake food powder removal.

Chemical industry: Clean treatment of granular chemical tablets.