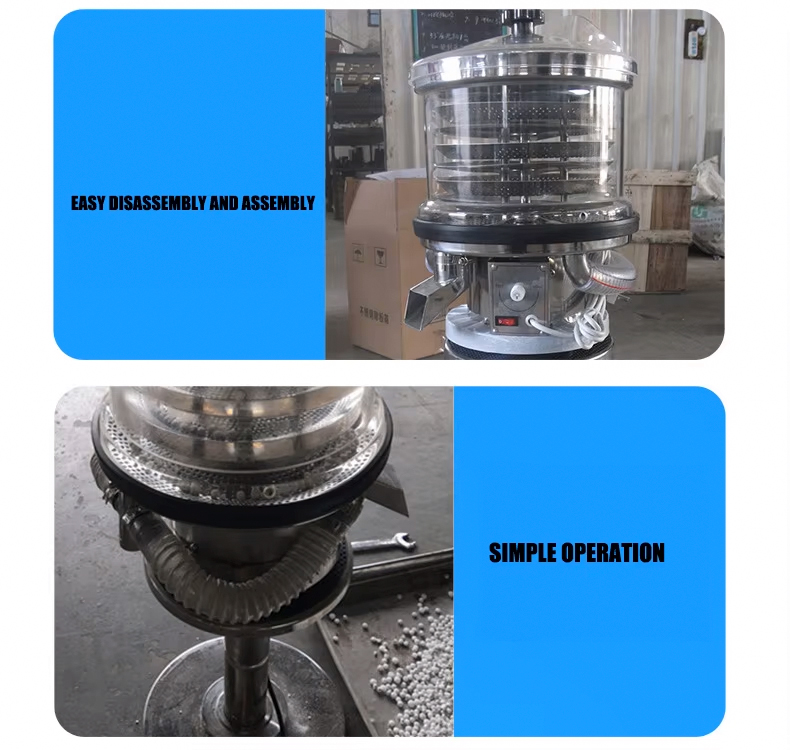

This Uphill Tablet Dehuster is an efficient dust removal device designed specifically for tablet production lines, suitable for dust removal and upward conveying of tablets after compression. Its compact structure and easy operation can effectively remove residual dust on the surface of tablets and smoothly transport them to the next process, such as metal detectors or packaging machines.

The equipment is made of food grade stainless steel material, which meets GMP standards and is widely used in tablet processing applications with high cleanliness requirements in industries such as pharmaceuticals, food, and chemicals.

1. Tablets enter the horizontal rotating channel from the feeding port, and the rotating polishing brush and spiral mechanism evenly push the tablets while using slight friction to peel off the dust adhering to the surface.

2. The stripped dust is promptly sucked out by the connected vacuum cleaner to ensure the cleanliness and smoothness of the finished tablets.

3. The discharge port outputs clean tablets, which can be connected to metal detectors or packaging machines.

| Model | CFQ-310 |

|---|---|

| Capacity | 550,000pcs/hour |

| Max Dimensions | Φ25mm |

| Compressed Air | 1.8m³/min-0.01MPa |

| Vacuum | 0.1m³/min-0.05MPa |

| Power Supply | 220V 50Hz 1P/ 110V 60Hz 1P |

| Power | 75W |

| Idle Load Noise | ≤60 dB |

| Inlet Height | 86-100cm |

| Size | 380*340*890mm |

| Machine Weight (kg) | 31.5kg |

Efficient polishing and dust removal: The powder removal effect is good, and the surface of the tablets is bright and clean.

Horizontal structure design: convenient for connecting subsequent equipment, such as metal inspection machines and packaging machines.

Compact structure: small footprint, flexible installation, and easy mobility.

All stainless steel manufacturing: Made of 304 or 316L stainless steel material, corrosion-resistant and easy to clean.

Low noise operation: minimal vibration and low noise during operation, safe and environmentally friendly.

Wide applicability: can handle circular and irregular tablets, with strong versatility.

Flexible adjustment: Supports adjusting the discharge height to meet the needs of different production lines.

Pharmaceutical industry: dust removal and polishing treatment after tablet pressing.

Health product industry: polishing and cleaning of chewable tablets and vitamin tablets.

Food industry: Candy and flake food powder removal.

Chemical industry: Clean treatment of granular chemical tablets.