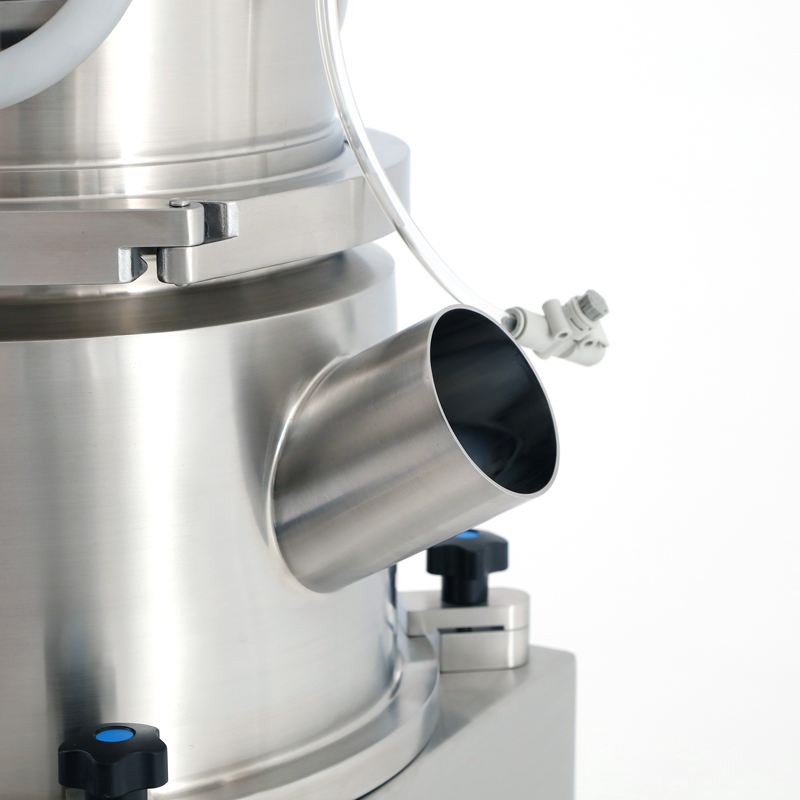

Upward tablet dust collector is a specialized equipment used in the post-processing process of tablet production, mainly used to remove dust and impurities on the surface of tablets, while also improving the height of tablets and facilitating subsequent process connections (such as metal detection, packaging, etc.). This equipment is made of high-quality stainless steel, with a reasonable structure, stable operation, and easy cleaning. It is an indispensable and important equipment in the pharmaceutical industry's GMP certification.

The tablets enter the spiral sieve channel through the feeding port, and during the upward movement driven by the motor, they continuously flip, rub, and vibrate, causing the dust adhering to the surface of the tablets to be completely peeled off. The stripped dust is promptly sucked out through the vacuum suction port, and the clean tablets are output from the top discharge port and enter the next process.

| Model | SZS-750 |

|---|---|

| Capacity(pcs/hour) | 800,000pcs/h(depending on dia 6mm) |

| Tablet diameter | dia 3mm-25mm |

| Inlet height | 825-1005mm |

| Outlet height | 1230-1410mm |

| Dedusting distance | 7.5m |

| Compressed air | 0.1m3/h (0.05MPa) |

| Vacuum cleaning | 2.7m3/h (-0.1MPa) |

| Power supply | 110V 60Hz / 220V 50Hz 0.1kw |

| Outline dimensions | 550*550*(1365-1545)mm |

| Machine weight | 80kgs |

It can continuously press various specifications of circular or irregular tablets, suitable for large-scale production.

The whole machine is made of stainless steel, which meets GMP standards and is dustproof and corrosion-resistant.

Transparent windows facilitate observation of the operation process, and are easy to clean and maintain.

Pressure, tablet weight, and thickness can be adjusted separately to ensure consistency of the finished tablets.

Equipped with overload protection device to prevent machine damage.

Prolongs equipment life and reduces maintenance frequency.

Single rotation can press multiple pieces, improving production efficiency.

Pharmaceutical industry: tablets, vitamin tablets, herbal extract tablets, etc.

Food industry: milk tablets, candy tablets, mint tablets, enzyme tablets, etc.

Chemical industry: catalyst tablets, deodorizing tablets, aromatic tablets, etc.

Electronic/metallurgical industry: battery material pressing, alloy powder pressing, etc.