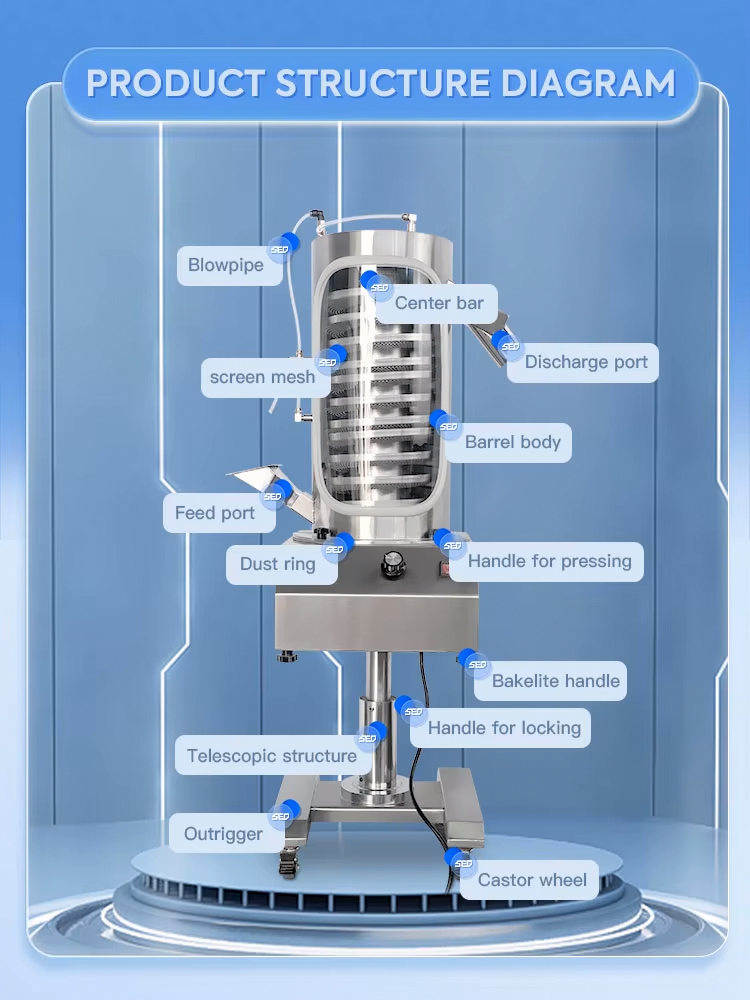

Upward tablet dust collector is a specialized equipment used in the post-processing process of tablet production, mainly used to remove dust and impurities on the surface of tablets, while also improving the height of tablets and facilitating subsequent process connections (such as metal detection, packaging, etc.). This equipment is made of high-quality stainless steel, with a reasonable structure, stable operation, and easy cleaning. It is an indispensable and important equipment in the pharmaceutical industry's GMP certification.

The tablets enter the spiral sieve channel through the feeding port, and during the upward movement driven by the motor, they continuously flip, rub, and vibrate, causing the dust adhering to the surface of the tablets to be completely peeled off. The stripped dust is promptly sucked out through the vacuum suction port, and the clean tablets are output from the top discharge port and enter the next process.

| Model | SZS230 |

|---|---|

| Production capacity (pcs/h) | 800,000 (Φ6) |

| Power (W) | 150 |

| Dedusting distance (m) | 6 |

| Max. tablet diameter. (mm) | Φ25 |

| Power supply | 220V/110V, 50Hz/60Hz, 1P |

| Compressed air | 0.1 m³/min~0.1MPa |

| Vacuum cleaning | 2.5 m³/min~0.1MPa |

| Noise (dB) | <75 |

| Dimension (mm) | 500*550*1350-1500 |

| Weight (kg) | 70 |

Efficient dust removal: Multi angle vibration cleaning tablets with a dust removal rate of up to 99%.

Upward conveying: The unique spiral channel structure achieves the lifting and conveying of tablets.

Visualization window: Transparent cover, clear and visible operating status, easy to observe and maintain.

GMP standard: The entire machine is made of 304/316L stainless steel material, which complies with pharmaceutical production standards.

Easy to operate: one click start, support speed regulation function, adapt to various production rhythms.

Low noise operation: adopting a silent design, low noise, and improving the comfort of the working environment.

Multi functional interface: can seamlessly connect with metal detection machines and automatic packaging machines.

Pharmaceutical industry: dust removal in tablet production and enhanced conveying.

Food industry: Powder removal and cleaning of compressed foods such as candies and chewable tablets.

Chemical industry: Dust removal treatment of sheet-like chemical products.

Health product industry: Dust removal and cleaning after the production of tablet health products.